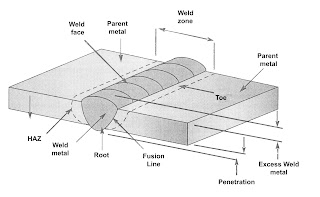

Features of the Completed Weld

- Parent metal Metal to be joined or surfaced by welding, braze welding or brazing

- Filler metal Metal added during welding, braze welding, brazing or surfacing

- Weld metal All metal melted during the making of a weld and retained in the weld

- Heat-affected zone (HAZ) The part of the parent metal metallurgically affected by the heat of welding or thermal cutting but not melted

- Fusion line Boundary between the weld metal and the HAZ in a fusion weld

- Weld zone Zone containing the weld metal and the HAZ

- Weld face The surface of a fusion weld exposed on the side from which the weld has been made

- Root Zone on the side of the first run furthest from the welder

- Toe Boundary between a weld face and the parent metal or between runs. This is a very important feature of a weld since toes are points of high stress concentration and often are initiation points for different types of cracks (eg fatigue and cold cracks). To reduce the stress concentration, toes must blend smoothly into the parent metal surface

- Excess weld metal Weld metal lying outside the plane joining the toes. Other non-standard terms for this feature are reinforcement and overfill

Features of the Completed Weld

Reviewed by belajar koor

on

10:04 PM

Rating:

Reviewed by belajar koor

on

10:04 PM

Rating:

Reviewed by belajar koor

on

10:04 PM

Rating:

Reviewed by belajar koor

on

10:04 PM

Rating:

No comments: