Definition and Types of Solid Inclusion according to BS EN ISO 6520-1

Types of solid inclusions:

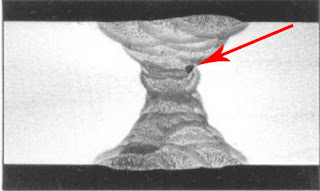

- Slag inclusions

- Incomplete slag removal from underlying surface of multi-pass weld Prevention: Improve inter-run slag removal

- Slag flooding ahead of arc Prevention: Position work to gain control of slag Welder needs to correct electrode angle

- Entrapment of slag in work surface Prevention: Dress/make work surface smooth

- Flux inclusions Flux trapped during welding which is an irregular shape so differs in appearance from a gas pore. Appear only in flux associated welding processes (ie MMA, SAW and FCAW).

- Unfused flux due to damaged coating Prevention: Use electrodes in good condition

- Flux fails to melt and becomes trapped in the weld (SAW or FCAW) Prevention: Change the flux/wire. Adjust welding parameters ie current, voltage etc to produce satisfactory welding conditions

- Oxide inclusions Oxides trapped during welding which is an irregular shape so differs in appearance from a gas pore.

- Metallic inclusions (Tungsten, Copper, other metal) Particles of tungsten can become embedded during TIG welding appears as a light area on radiographs as tungsten is denser than the surrounding metal and absorbs larger amounts of X-/gamma radiation.

- Contact of electrode tip with weld pool Prevention: Keep tungsten out of weld pool; use HF start

- Contact of filler metal with hot tip of electrode Prevention: Avoid contact between electrode and filler metal

- Contamination of the electrode tip by spatter from the weld pool Prevention: Reduce welding current; adjust shielding gas flow rate

- Exceeding the current limit for a given electrode size or type Prevention: Reduce welding current; replace electrode with a larger diameter one

- Extension of electrode beyond the normal distance from the collet, resulting in overheating of the electrode Prevention: Reduce electrode extension and/or welding current

- Inadequate tightening of the collet Prevention: Tighten the collet

- Inadequate shielding gas flow rate or excessive draughts resulting in oxidation of the electrode tip Prevention: Adjust the shielding gas flow rate; protect the weld area; ensure that the post gas flow after stopping the arc continues for at least five seconds

- Splits or cracks in the electrode Prevention: Change the electrode, ensure the correct size tungsten is selected for the given welding current used

- Inadequate shielding gas (eg use of argon-oxygen or argon-carbon dioxide mixtures that are used for MAG welding) Prevention: Change to correct gas composition

Slag trapped during welding which is an irregular shape so differs in appearance from a gas pore.

- Causes:

- Causes:

Causes:

Heavy millscale/rust on work surface

Prevention: Grind surface prior to welding

A special type of oxide inclusion is puckering, which occurs especially in the case of aluminium alloys. Gross oxide film enfoldment can occur due to a combination of unsatisfactory protection from atmospheric contamination and turbulence in the weld pool.

- Causes:

Definition and Types of Solid Inclusion according to BS EN ISO 6520-1

Reviewed by belajar koor

on

2:30 PM

Rating:

Reviewed by belajar koor

on

2:30 PM

Rating:

Reviewed by belajar koor

on

2:30 PM

Rating:

Reviewed by belajar koor

on

2:30 PM

Rating:

Great

ReplyDelete