Definition and Types of Cracks according to BS EN ISO 6520-1

Crack is imperfection produced by a local rupture in the solid state, which may arise from the effect of cooling or stresses. Cracks are more significant than other types of imperfection as their geometry produces a very large stress concentration at the crack tip making them more likely to cause fracture.

Types of crack:

- Longitudinal.

- Transverse.

- Radiating (cracks radiating from a common point).

- Crater.

- Branching (group of connected cracks originating from a common crack).

These cracks can be situated in the:

- Weld metal.

- HAZ.

- Parent metal.

Exception: Crater cracks are found only in the weld metal.

Depending on their nature, these cracks can be:

- Hot cracks(ie solidification or liquation cracks).

- Precipitation induced cracks(ie reheat cracks present in creep resisting steels).

- Cold cracks(ie hydrogen induced cracks).

- Lamellar tearing.

Hot cracks

Depending on their location and mode of occurrence, hot cracks can be:

- Solidification cracks: Occur in the weld metal (usually along the centreline of the weld) as a result of the solidification process.

- Liquation cracks: Occur in the coarse grain HAZ, in the near vicinity of the fusion line as a result of heating the material to an elevated temperature, high enough to produce liquation of the low melting point constituents placed on grain boundaries.

Solidification cracks

Generally, solidification cracking can occur when:

- Weld metal has a high carbon or impurity (sulphur, etc) content.

- The depth-to-width ratio of the solidifying weld bead is large (deep and narrow).

- Disruption of the heat flow condition occurs, eg stop/start condition.

The cracks can be wide and open to the surface like shrinkage voids or

sub-surface and possibly narrow. Solidification cracking is most likely to occur in compositions and result in a

wide freezing temperature range. In steels this is commonly created by a

higher than normal content of carbon and impurity elements such as sulphur

and phosphorus. These elements segregate during solidification, so that

intergranular liquid films remain after the bulk of the weld has solidified. The thermal shrinkage of the cooling weld bead can cause these to rupture and

form a crack.

It is important that the welding fabricator does not weld on or near metal

surfaces covered with scale or contaminated with oil or grease. Scale can

have a high sulphur content and oil and grease can supply both carbon and

sulphur. Contamination with low melting point metals such as copper, tin,

lead and zinc should also be avoided.

Hydrogen induced cracks

|  |

| Root (underbead) crack | Toe crack |

Hydrogen induced cracking occurs primarily in the grain coarsened region of

the HAZ and is also known as cold, delayed or underbead/toe cracking. It

lies parallel to the fusion boundary and its path is usually a combination of

inter and transgranular cracking. The direction of the principal residual

tensile stress can in toe cracks cause the crack path to grow progressively

away from the fusion boundary towards a region of lower sensitivity to

hydrogen cracking. When this happens, the crack growth rate decreases

and eventually arrests.

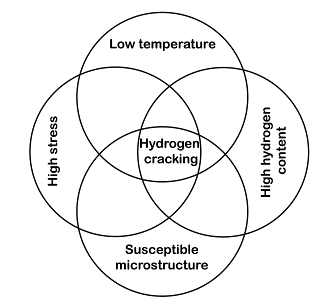

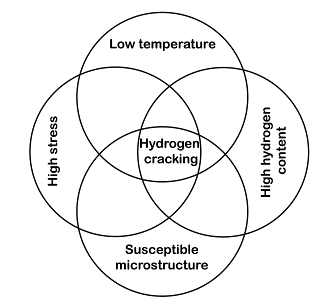

Four factors are necessary to cause HAZ hydrogen cracking:

If any one factor is not satisfied, cracking is prevented, so can be avoided through control of one or more factors:

Lamellar tearing occurs only in rolled steel products (primarily plates) and its main distinguishing feature is that the cracking has a terraced appearance.

Cracking occurs in joints where:

Four factors are necessary to cause HAZ hydrogen cracking:

- Hydrogen level > 15ml/100g of weld metal deposited

- Stress > 0.5 of the yield stress

- Temperature < 300°C

- Susceptible microstructure > 400HV hardness

If any one factor is not satisfied, cracking is prevented, so can be avoided through control of one or more factors:

- Apply preheat slow down the cooling rate and thus avoid the formation of susceptible microstructures.

- Maintain a specific interpass temperature (same effect as preheat).

- Postheat on completion of welding to reduce the hydrogen content by allowing hydrogen to diffuse from the weld area.

- Apply PWHT to reduce residual stress and eliminate susceptible microstructures.

- Reduce weld metal hydrogen by proper selection of welding process/consumable (eg use TIG welding instead of MMA basic covered electrodes instead of cellulose).

- Use a multi-run instead of a single run technique and eliminate susceptible microstructures by the self-tempering effect, reduce hydrogen content by allowing hydrogen to diffuse from the weld area.

- Use a temper bead or hot pass technique (same effect as above).

- Use austenitic or nickel filler to avoid susceptible microstructure formation and allow hydrogen to diffuse out of critical areas).

- Use dry shielding gases to reduce hydrogen content.

- Clean rust from joint to avoid hydrogen contamination from moisture present in the rust.

- Reduce residual stress.

- Blend the weld profile to reduce stress concentration at the toes of the weld.

Lamellar tearing occurs only in rolled steel products (primarily plates) and its main distinguishing feature is that the cracking has a terraced appearance.

Cracking occurs in joints where:

- A thermal contraction strain occurs in the through-thickness direction of steel plate.

- Non-metallic inclusions are present as very thin platelets, with their principal planes parallel to the plate surface.

- Use a clean steel with guaranteed through-thickness properties (Z grade).

- A combination of joint design, restraint control and welding sequence to minimise the risk of cracking.

Definition and Types of Cracks according to BS EN ISO 6520-1

Reviewed by belajar koor

on

10:46 AM

Rating:

Reviewed by belajar koor

on

10:46 AM

Rating:

Reviewed by belajar koor

on

10:46 AM

Rating:

Reviewed by belajar koor

on

10:46 AM

Rating:

Definition And Types Of Cracks According To Bs En Iso 6520-1 - All About Welding Inspector World >>>>> Download Now

ReplyDelete>>>>> Download Full

Definition And Types Of Cracks According To Bs En Iso 6520-1 - All About Welding Inspector World >>>>> Download LINK

>>>>> Download Now

Definition And Types Of Cracks According To Bs En Iso 6520-1 - All About Welding Inspector World >>>>> Download Full

>>>>> Download LINK zL